Bag Palletizers

Bag palletizers are essential automation solutions designed to streamline the palletizing process in manufacturing plants. They function by systematically stacking and organizing bags onto pallets, ensuring stability and efficiency. Bag palletizing enhance operational workflows by improving precision and consistency.

In modern logistics and supply chain management, bag palletizers play a crucial role in reducing manual labor, improving productivity, and maintaining consistency in pallet formation. Compared to traditional palletizing methods, automated bag palletizing systems significantly enhance load stability and reduce manpower injuries, leading to a more reliable and efficient operation.

At PFA Equipment, we specialize in providing high-quality bag palletizing solutions that cater to a wide range of industries. With years of expertise in automation and material handling, we ensure that businesses benefit from innovative and efficient palletizing systems tailored to their unique operational requirements.

Benefits of Using Bag Palletizers

Businesses across various industries are increasingly turning to bag palletizers to enhance productivity and safety in their operations. These machines streamline the palletizing process, allowing for faster, more efficient handling of materials while reducing reliance on manual labor.

Integrating bag palletizers into production operations offers several key benefits:

- Increased Efficiency: Automating the palletizing process speeds up production lines, reducing bottlenecks and increasing throughput.

- Reduced Labor Costs: By minimizing the need for manual labor, businesses can lower operational expenses and reallocate human resources to more critical tasks.

- Enhanced Safety: Automation reduces workplace injuries associated with repetitive heavy lifting and manual handling of bags.

- Improved Logistics and Supply Chain Operations: Consistent palletizing leads to better space utilization in warehouses and transport vehicles, optimizing overall logistics performance.

- Cost Savings and ROI: The initial investment in a bag palletizer is offset by long-term savings in labor and efficiency improvements.

Types of Bag Palletizers

There are multiple types of bag palletizers designed to meet different industry needs. Each type offers unique advantages based on production demands, automation levels, and space constraints.

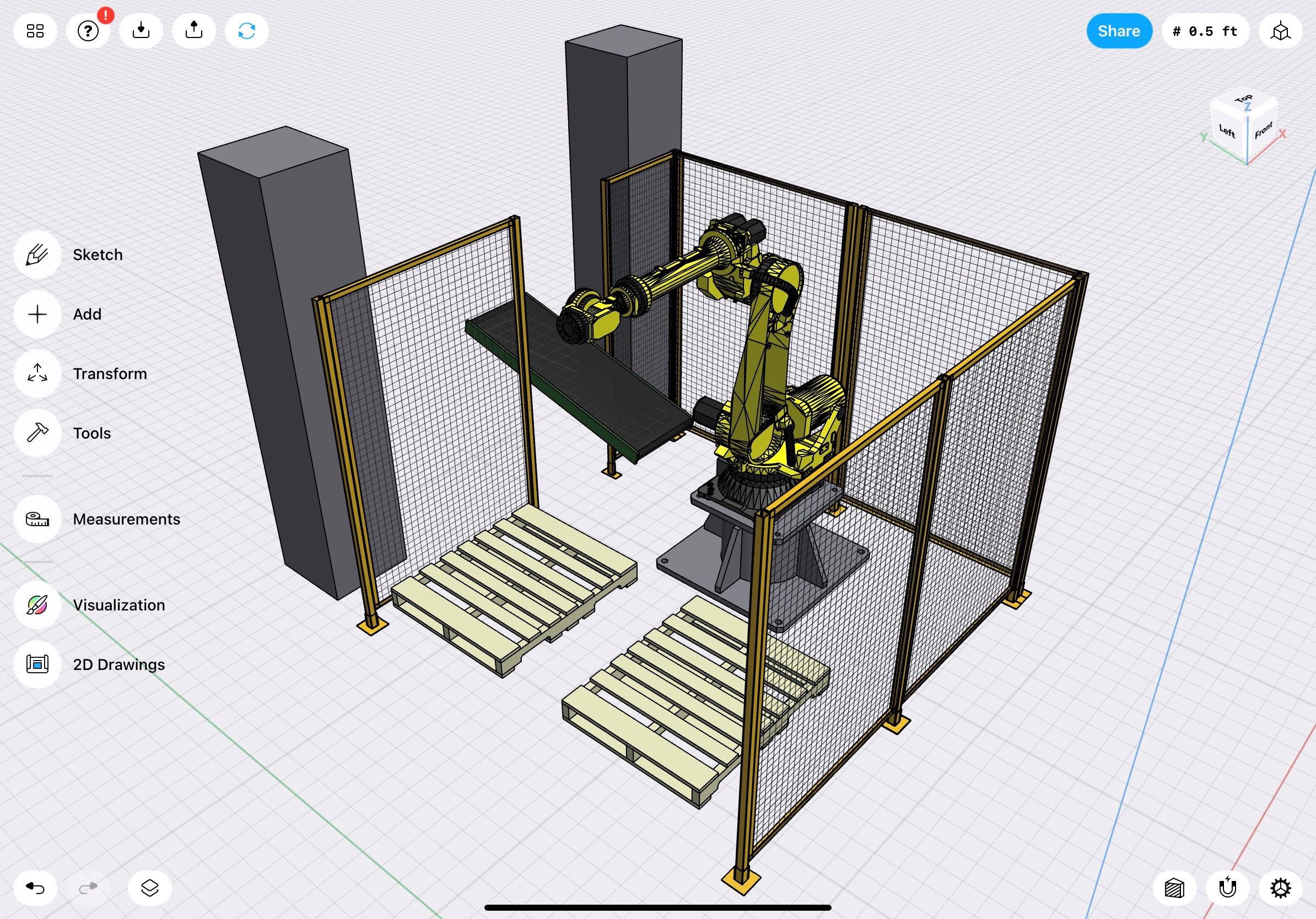

- Robotic Bag Palletizers: Robotic palletizers are flexible and programmable systems that handle multiple bag types and bag sizes, making them ideal for industries requiring adaptability.

- High-Level Conventional Bag Palletizers: Operating at higher elevations, these machines offer increased speed and precision, making them ideal for large-scale production lines.

Robotic palletizers provide greater flexibility and require less maintenance compared to conventional palletizers, making them an excellent choice for industries with variable packaging needs. Conventional palletizers offer faster rates, better load appearance and in a lot of cases more staple pallet loads. Selecting the right type of bag palletizer depends on production volume, facility layout, and specific operational requirements.

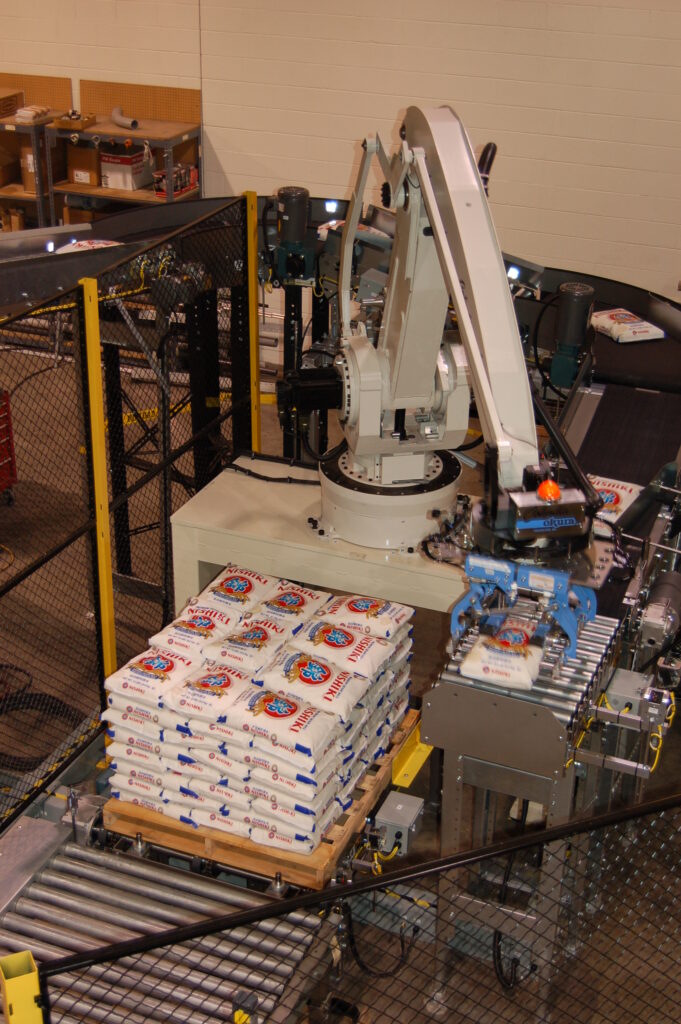

Robotic Bag Palletizers

Rebuilt Robotic Bag Palletizer

Available through PFA are Rebuilt Robotic Bag Palletizers with new equipment warranty. Many of the components and related equipment are new. This will result in substantial cost savings in the purchase of robotic bag palletizers.

High Level Conventional Bag Palletizer

90 Degree Pallet Turntable

This conveyor can be used for empty pallets to feed a palletizer or full pallets exiting a palletizer. They are capable of discharging and receiving pallets in different directions.

Live Roller Pallet

Live roller pallet conveyor for empty or full pallets to go in opposite direction of pallet runners.

Wire Mesh Pallet Conveyor

Wire mesh pallet conveyor for use with empty or full pallets. Can be used regardless of the direction of runners.

Choosing the Right Bag Palletizer for Your Business

Choosing the appropriate bag palletizer is a crucial decision that can impact operational efficiency and long-term cost savings. With various options available, businesses must carefully assess their needs before making an investment.

- Capacity and Speed Requirements: Choose a palletizer that matches your production volume to ensure efficiency.

- Flexibility: Consider the ability to handle various bag sizes and materials.

- Cost vs. ROI: Evaluate initial investment costs against long-term operational savings.

- Space Constraints: Ensure the palletizer fits within your facility’s layout.

- Integration Capability: Select a system compatible with existing warehouse automation, conveyor systems, and other packaging equipment.

Common mistakes to avoid include selecting a bag palletizer without considering future scalability and neglecting the importance of maintenance and support services.

Integrating Bag Palletizers With Existing Systems

Successfully integrating bag palletizers into an existing production system requires strategic planning and execution. Ensuring that the new equipment complements current operations can maximize efficiency and minimize disruptions.

Here are a few things to consider when integrating bag palletizers:

- Compatibility with Existing Systems: Ensure seamless communication between the palletizer and existing bag conveyor system.

- Space and Workflow Adjustments: Optimize floor layout for smooth operation and minimal disruption.

- Employee Training: Provide comprehensive training to staff inefficient operation and maintenance.

- Minimizing Downtime: Implement a phased installation approach to prevent operational disruptions.

Incorporating material handling innovations such as bag palletizing systems and bulk bag fillers can further enhance workflow efficiency. Businesses that take a strategic approach to integration will experience smoother transitions and increased productivity.

Bag Palletizers: A Smart Investment

Bag palletizers transform warehouse operations by enhancing efficiency, reducing costs, and improving overall logistics performance. For businesses considering automation, investing in palletizing technology is a strategic move toward long-term supply chain optimization. Selecting the right palletizer and ensuring seamless integration will lead to improved productivity, safety, and cost-effectiveness, making it a critical component of modern warehouse management.

By leveraging palletizing solutions, companies can significantly improve operational output, while, bag palletizing systems ensure precision and speed. A well-integrated bagging machine, complete with automated pallet stacking and bag flattener capabilities, allows businesses to optimize their processes. Investing in advanced bagging equipment ensures streamlined operations and effective logistics optimization.

Contact

Phone

(949) 331-0764

info@pfallc.co

Address

6 Cordoba

Irvine, CA 92614