Bag Filler and Packaging Machines

PFA has access to the right equipment for your bagging needs. We can help choose the right bag as well as assist in sizing.

Another important factor in bag filling is the design of the feed hopper to the bagging machine. Depending on product characteristics, bag fillers require proper feed hoppers to insure consistent flow and head pressure. Repeatable bag weights and speed need correct feed hopper.

Valve Bag Fillers

Valve Bag Fillers are basically divided into three styles. These are air, impeller, and auger valve bag packers. Each style has various models. Product, production rates and weight accuracy desired determine the best model to use.

All valve bag fillers are gross weighing and performance is greatly depending on product and proper feed hopper to filler. For best production rates, weight accuracy and minimal dust it is very important to have correct valve bags. This means they are sized for the product that is being filled and the type of construction of the bag, meaning paper, valve size, and if needed perforations. Proper bags are most important if using automatic bag placer.

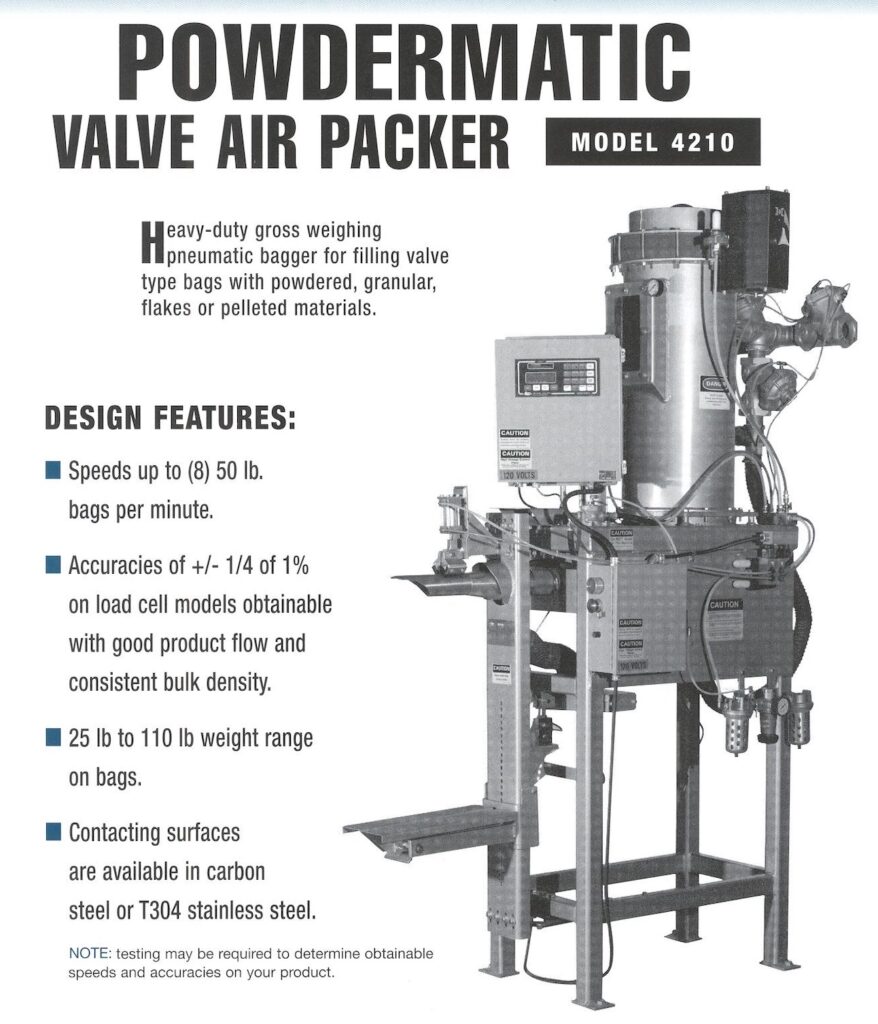

Chantland Model 4210 PowderMatic Pneumatic Filler

It is a gross weigh bagger for either plastic or paper valve bags. Fill weight ranges from 25 lb to 110 lb bags with speeds of up to 16 bags per minute. Rates and accuracy are determined by bag weights and type of product. It is used in a variety of industries such as fertilizer, aggregates, seeds, minerals, building products, and many other non-abrasive products. It is available with a scale beam weigh system or electronic weigh and mild steel or stainless-steel product contact.

The chamber size is based on the bulk density of the product. It has an inlet butterfly valve that cycles with every bag and a discharge fill spout that is sized for the bag valve size. The chamber is gravity filled and when the bag starts the butterfly closes a pinch tube opens at fill spout and low-pressure high volume air is introduced so the product is blown into the bag. When the bag comes to weight, the product is cut-off at the fill spout and the butterfly valve opens. The size of the blower assembly is determined by the product and generally, they are 5hp or 7.5 hp. They have an inlet filter, silencer, weighted relief valve, and blower all mounted on an elevated stand. Piping to packers and motor controls are by others.

Standard 4210

- Scale-beam weighing

- Pneumatic filler

- Manual start

- Manual bag discharge

- Pneumatic bag clamp

- Hinged bottom chamber with canvas fluidizing pad

- Butterfly valve with actuator

- Product slight glass

- Chamber exhaust

- Mild steel construction

Options

- Electronic weighing system digital controller

- Automatic bag start

- Automatic bag discharge

- Low-pressure high-volume blower assembly

- Stainless steel product contact

- Anti-corrosive package

- Special paint finishes

Chantland Model 2010 PS Pneumatic Filler

This is the premium air packer for filling abrasive and semi-abrasive products. These products include but are not limited to dry mixed concrete, block mortar, stucco, sand, sanded repair products, brick mortars, and minerals. The 2010 PS uses a low- pressure high- volume blower to pneumatically fill bags, pails, and drums. Rates for 50 lb. bags can be 18 per minute depending on the material. Weight accuracy is +-3 oz. to 6 oz. depending on the product and packer surge hopper.

The Plug Stack filler consists of a chamber with a column inlet, a discharge spout, a mechanical or electronic weigh system, and a low-pressure high-volume blower assembly. A constant head of material is required as the material is blown into the container and requires constant feed. The size of packer surge hopper is determined by the material.

Standard Features

- Scale-beam gross weighing

- Manual start

- Manual discharge

- Pneumatic bag clamp

- Dust collection hood and manifold

- Mild steel construction

Options

- Automatic start

- Automatic discharge

- Low-pressure high-volume blower assembly

- Load cell weighing with controller

- Stainless steel product contact surfaces

- Special paint finishes

Chantland Model 4010 Impeller Packer

This impeller packer is primarily used for filling valve bags with powdered products from 100 mesh to over 325 mesh. They are used for bagging fine products like gypsum, limestone, talc, cement, clays, marble, or any mineral that is a fine mesh. They have also been used for fine sanded products such as thin-set, grouts. Repair products and flooring products. Rates of 6 to 10 bags per minute are available on 20 lb. to 110 lb. valve bags depending on material.

Standard Features

- Scale-beam gross weighing

- Impeller hup feed, 4 blades

- Manual bag start

- Manual bag discharge

- Pneumatic bag clamps

- Dust collection hood and manifold

- NEMA 12 electrical

- Transformer in MCP for motor control

- Mild steel construction

Options

- Automatic bag start

- Automatic bag discharge

- VFD

- Electronic weighing with controller

- Stainless steel product contact surfaces

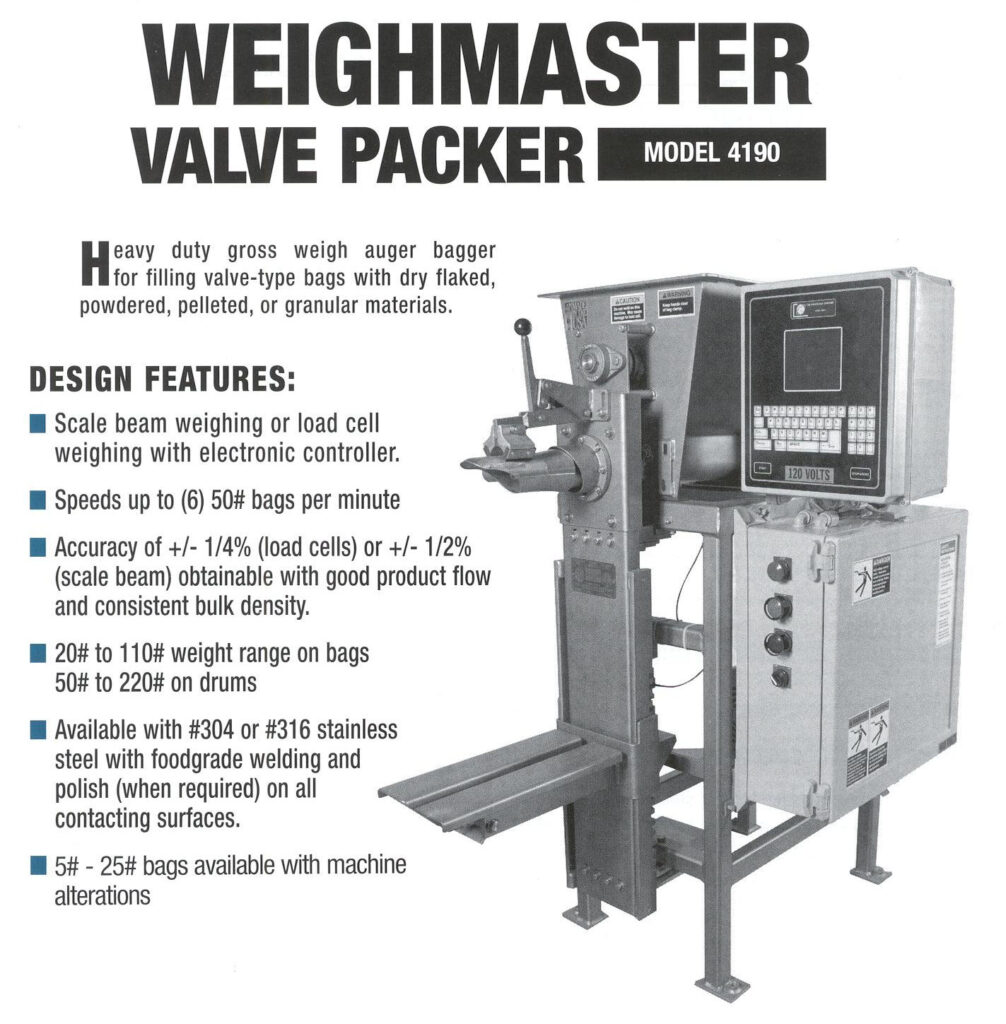

Chantland Model 4190 Weighmaster

This auger packer also known as a screw packer is designed to fill valve bags, bag in boxes, pails and containers with non-abrasive material. Product rates up to five 50 lb. bags per minute. Bag weights can range from 20 to 110 lbs. They are available in mild steel as well as stainless steel food grade. They are used in the food, seed, fertilizer, minerals, and animal feed industries.

Standard Features

- Scale-beam gross weighing

- Auger feeder

- Manual start

- Manual bag clamp

- Manual bag discharge

- Safety interlocked clean-out door

- MEMA 12 electrical

- Dust collection hood and manifold

- Mild steel construction

Options

- Automatic fill start

- Automatic discharge

- Pneumatic bag clamps

- Load cell weighing with controller

- Dust collection hood and manifold

- Variable Speed Drive

- Agitator assembly about feed auger

- Open moth filler attachment

- Drum fill attachment

- Stainless steel contact surface

- Food grade stainless steel contact surfaces

- Complete washdown including MCP

Automatic Valve Bag Placer

The model 4410 is for placing valve bags on one or two valve bag packers. The model 4420 is for placing valve bags on three spouts. The placer is designed to work with paper valve bags and some poly valve bags. Depending on model of valve bag filler, fill time and material the placer will do 8 to up to 12 bags per minute. Valve bag quality is very important for machine to operate at full capacity.

Standard Features

- Automatic start with no-bag, no-dump interlock

- Left hand or right hand in-feed

- Adjustable to various bag sizes

- NEM 12 electrical

- Mild steel construction

Options

- Anti-corrosive package

- Special paint finishes

- Special electrical packages

Open-Mouth Bag Fillers

Designed to fill open-mouth bags, boxes, pails, or drums with dry bulk products. Available with scale beam or electronic weigh systems. They come in single or duplex scale and by gravity, auger, vibrating, and belt feed.

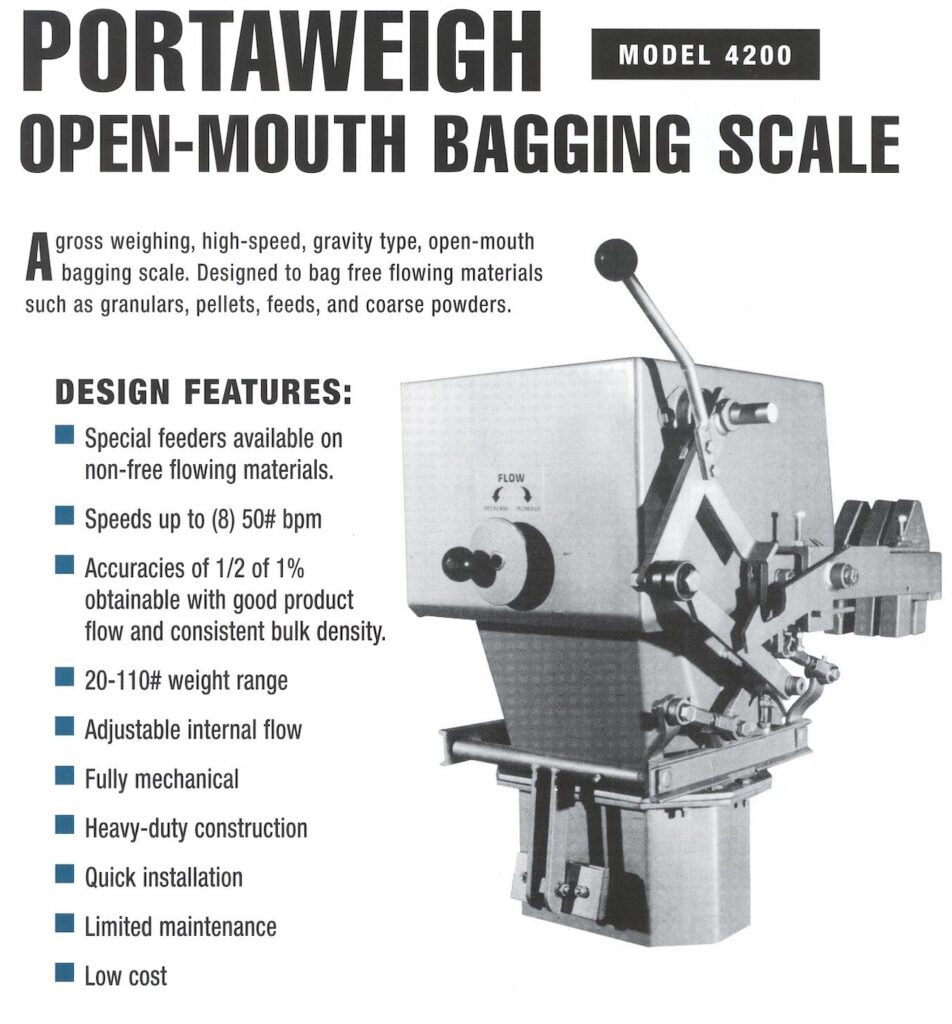

Model 4200

A gross weighing, high-speed, gravity type open mouth bag, pail, or box filler. Products include but are not limited to feed, seeds, grains, aggregate, sand, rock salt, charcoal, and minerals. Weights range 20 lbs. to 110 lbs.

Gravity type fill is designed to mate to a surge hopper. Product feeds through the filler, and as the weight in the container equals the counterbalance weight value, the clamshell gate closes, ending the fill cycle.

Standard Features

- Scale-beam weighing

- Gravity feeder

- Mechanical catch gate release

- Manual bag clamps

- Adjustable flow gate

- Either 5-1/2” X 9” oval spout or 6-1/2” X 11” oval spout

- Mild steel construction

Options

- Foot pedal mechanical switch

- Pneumatic bag clamps

- Pneumatic catch gate release

- Load cell weighing with controller

- Special spout sizes

- Mounting stand

- Stainless steel product contact surfaces

- Food grade construction

- Anti-corrosive package

- Special paint finishes

- Special electrical packages

Model 4234

Gross weighing, open-mouthed, bagging scale.

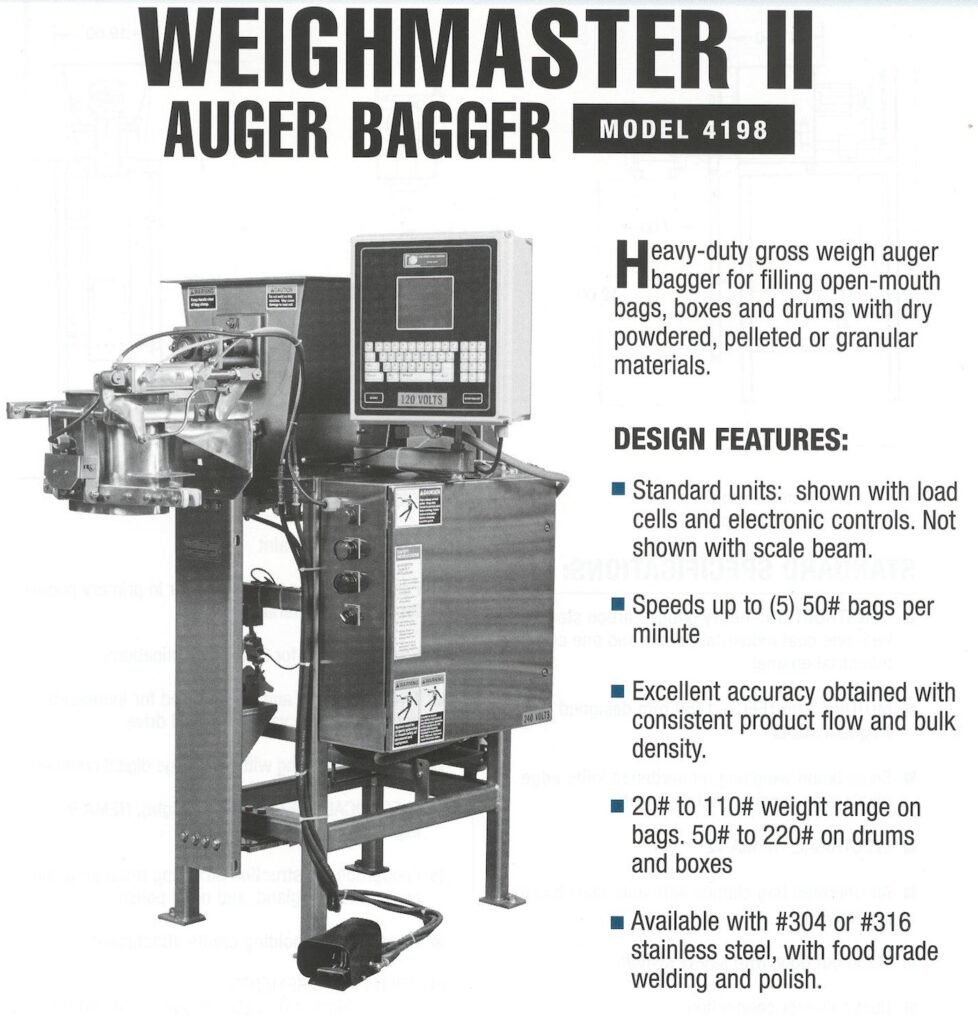

Model 4198

Heavy-duty gross weigh auger bagger for filling open-mouth bags, boxes, and drums with dry powdered, pelleted or granular materials.

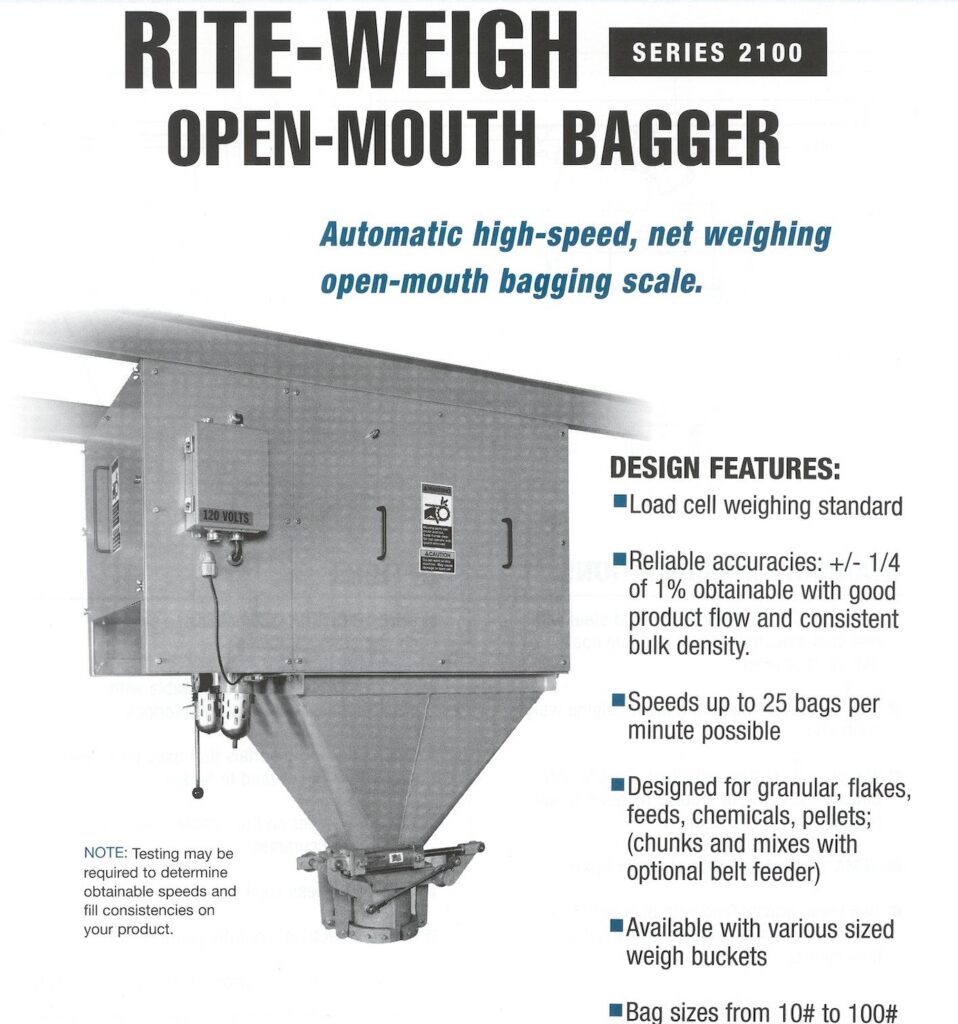

Rite-Weight Open-Mouth Bagger

Series 2011

Automatic high-speed, net weighing open-mouth bagging scale.